Experiment

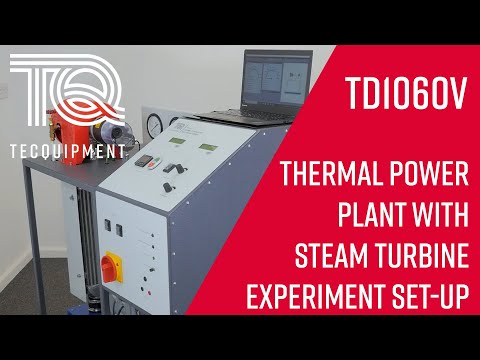

TD1060V

Thermal Power Plant with Steam Turbine

Mobile, laboratory-scale steam turbine that demonstrates fundamental thermodynamic principles of energy conversion and mechanical power measurement

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611Thermal Power Plant with Steam Turbine

A mobile, laboratory-scale steam plant for experiments in thermodynamic principles. It helps students to understand:

- Thermodynamic laws of energy conservation

- Steady flow energy equation

- Thermal efficiency

- Rankine cycle analysis

A mobile frame contains all the parts of the test set.

A variable-speed, low-voltage piston pump takes water from the reservoir and feeds it into a flash boiler. The thermostatically controlled flash boiler, which is electrically powered (no gas required), has a pressure-relief and thermal trip (200°C) fitted. Steam from the boiler moves up to and expands through the single stage, Ø127 mm axial turbine powering the electric dynamometer. The load applied by the dynamometer can be varied via the control panel.

The used steam is condensed through the steam-to-air heat exchanger. Cooling fans can be activated to control the temperature of the return water to the reservoir closing the cycle. Preheated feedwater increases the machine’s efficiency.

For quicker tests with easier recording of results, the steam turbine comes with TecQuipment’s Versatile Data Acquisition System (VDAS®) Onboard. The software is free to download from TecQuipment’s website. This system provides accurate real-time data capture, monitoring and display, calculation and charting of all the important readings on a computer.

Learning outcomes

- Demonstration of a steam power plant and its working cycle with electric power generation.

- Study about specific steam consumption and impact of steam flow rate on power generation.

- Examine the impact of loading and varying steam feed temperature on steam plant performance.

- Investigation of turbine speed, torque and power characteristics.

- Analysis of the steam plant performance to determine losses using energy balance equation.

- Comparison of the system with ideal Rankine cycle and determining Rankine, relative efficiencies.