Experiment

CE110

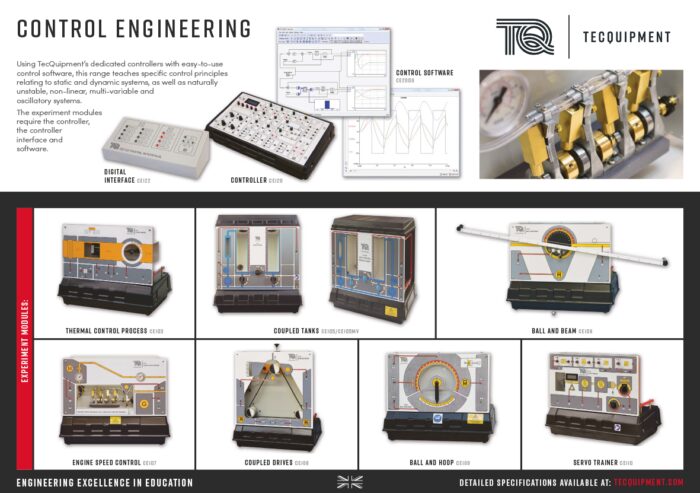

SERVO TRAINER

A compact self-contained bench mounting d.c. servo apparatus designed to allow students at all academic levels to investigate basic and advanced principles of control. In particular the CE110 deals with control issues relating to position and speed control in servo systems.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611SERVO TRAINER

The CE110 Servo Trainer shows d.c. servo position and speed control systems using typical industrial techniques. It has a d.c. servomotor, a d.c. generator and a flywheel mounted on a common shaft.

Analogue 0 to ±10 V control signals vary the servomotor shaft speed in either direction. An optical sensor measures the speed and shows it on a panel-mounted digital meter. The d.c. generator statically or dynamically loads the servomotor.

An electric clutch connects or disconnects the shaft to a 30:1 reduction gearbox for position control studies. A manual control allows the user to set a position control setpoint. To adjust the shaft inertia, the CE110 comes with two extra interchangeable inertia discs (flywheels).

For advanced experiments, the Servo Trainer includes extra ‘block’-type circuits that can add non-linear and fully adjustable effects of:

- Deadzone or ‘deadband’

- Anti-deadzone

- Hysteresis

- Saturation

These blocks are important in studies of servo systems because they mimic problems that happen in real applications.

Learning outcomes

- Basic tests and transducer calibration

- Response calculation and measurement

- Proportional and proportional plus integral control of servo-system speed

- Disturbance cancelling and feedforward control

- Angular position control: proportional control and velocity feedback

- Angular position control and the influence of nonlinearities

- Non-linear system characteristics