Food And Drink

An Appetite for Engineering

The food and drink industry encompasses some of the largest companies in the world, producing much of the products we consume on a day-to-day basis. These include our meat and fish, fresh fruit and vegetables, alcohol, coffee, biscuits and everything in between.

To support this system of global food and beverage mass production, requires vast amounts of highly skilled engineers. Beyond the creation of the products, new process and machinery have to be developed and maintained, where environmental conditions vary wildly.

The control methods, environmental control and mechanical knowledge needed for the industry can be learnt by students on TecQuipment's advanced educational range of equipment. Browse through some of our specially selected ranges providing the knowledge for the future engineers of the food and drink industry.

Product Ranges

-

Air Conditioning

Air Conditioning

-

Arches, Bridges And Trusses

Arches, Bridges And Trusses

-

Basic Elastic Properties

Basic Elastic Properties

-

Control Engineering Principles

Control Engineering Principles

-

Cooling

Cooling

-

Digital Control

Digital Control

-

Failure

Failure

-

Flow And Pressure Measurement

Flow And Pressure Measurement

-

Flow Visualisation

Flow Visualisation

-

Heat Transfer

Heat Transfer

-

Humidity

Humidity

-

Hydraulic Bench

Hydraulic Bench

-

Hydrostatics And Properties Of Fluids

Hydrostatics And Properties Of Fluids

-

Laminar And Turbulent Flow

Laminar And Turbulent Flow

-

Modular Fluid Power

Modular Fluid Power

-

Pipe Friction And Energy Loss

Pipe Friction And Energy Loss

-

Power System Ancillaries

Power System Ancillaries

-

Power System Laboratory

Power System Laboratory

-

Process Control

Process Control

-

Pumps And Turbines

Pumps And Turbines

-

Refrigeration

Refrigeration

-

Steam

Steam

-

Thermodynamic Principles

Thermodynamic Principles

-

VDAS e-lab

VDAS e-lab

-

Vibration

Vibration

-

Vibration

Vibration

-

Vortices And Cavitation

Vortices And Cavitation

Featured Products

DefleX

Digital image correlation (DIC) system designed to enhance the student learning experience, for real-time and post-process measurement and visualisation of deformations, strains and displacements in materials and shapes. Complements the teaching equipment.

DefleX

Digital image correlation (DIC) system designed to enhance the student learning experience, for real-time and post-process measurement and visualisation of deformations, strains and displacements in materials and shapes. Complements the teaching equipment.

TRANSMISSION LINE SIMULATOR

Investigates short, medium and long transmission line performance in single-phase and three-phase systems.

IDEAL GASES - BOYLE'S LAW

TD1000 - Experiment

TD1000 - Experiment

Shows the relationship between pressure and volume of an ideal gas at a fixed temperature.

WATER TO AIR HEAT EXCHANGERS

TD1007 - Experiment

TD1007 - Experiment

An experimental unit to show how cross-flow water to air heat exchangers work.

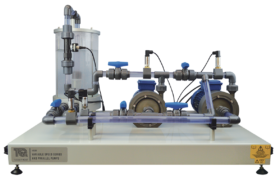

COUPLED TANKS APPARATUS

A self-contained, bench-mounting apparatus designed to allow students at all academic levels to investigate basic and advanced principles of open and closed-loop control of flowrate and liquid level in single and dual tank systems.

ENGINE SPEED CONTROL APPARATUS

A compact self-contained bench mounting apparatus designed to allow students at all academic levels to investigate basic and advanced principles of control including control of non-linear systems and inner-loop feedback techniques.

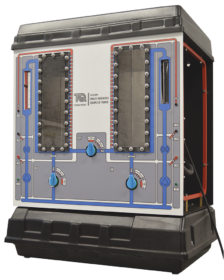

PLC PROCESS

Provides a physical system on which students can gain experience in the programming of programmable logic controllers (PLCs). The process is a model of a two-tank system typical of a chemical process in which liquids are measured before being mixed. The task for the student is to control liquid level and flow. For use with the PLC Trainer (CE123).

PROCESS TRAINER

A fully integrated and self-contained bench top process control apparatus containing valves, pumps, power supplies and ancillaries to allow flow, level, temperature and pressure control strategies to be investigated individually and in combinations.

COOLING TOWERS

EC1000V - Experiment

EC1000V - Experiment

Demonstrates the operational characteristics of an evaporative cooling tower.