Experiment

H405

PIPE SURGE AND WATER HAMMER

A self-contained unit for teaching the principles of pipe surge and water hammer.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611PIPE SURGE AND WATER HAMMER

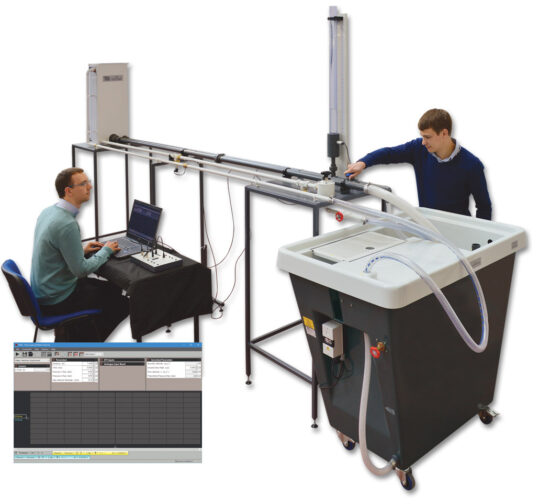

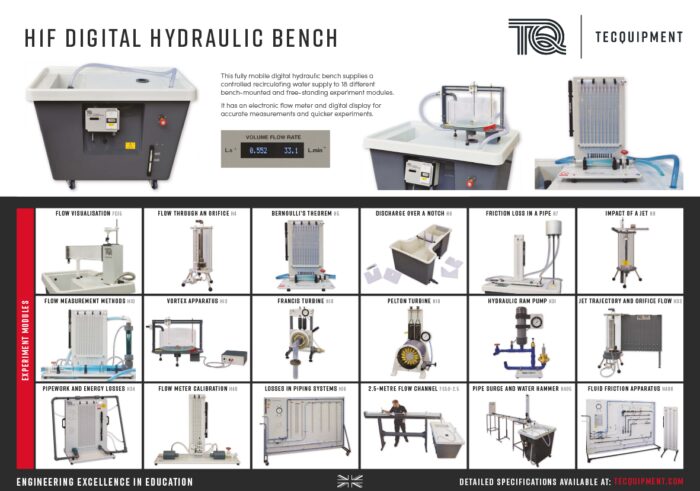

shows the transient effects of pipe surge and water hammer caused by sudden flow rate changes in pipes. The apparatus has two separate test pipes: one for pipe surge investigations and one for water hammer investigations. A header tank (reservoir of water) supplies both test pipes. This tank includes an internal float valve and an overflow for good engineering practice. A Digital Hydraulic Bench (H1F) supplies the header tank with a controlled flow of water via an inlet valve. The outlets from the test pipes flow into the measuring tank of the hydraulic bench.

The test pipe for surge investigations includes a clear plastic surge tower connected near its downstream end, and a control valve. A pressure transducer in the base of the surge tower connects to TecQuipment’s optional VDAS®.

For surge investigations, students adjust valves to create a steady flow from the header tank through the surge pipe. This flow creates a measurable head loss (due to friction) along the surge pipe from the header tank to the surge tower. To create the surge, students quickly shut the surge valve downstream of the surge pipe. VDAS displays and records the pressure surge in the surge tower. Students also examine the maximum surge height, and use VDAS® to measure the time from valve closure to maximum surge. They then repeat the experiment for different flows and therefore different values of head loss.

TecQuipment’s VDAS® (mkII) also allows students to study the surge decay waveform and compare it with a viscous damping model.

The test pipe for water hammer experiments has a special quick-closing valve at its downstream end. This pipe has two pressure transducers which connect to TecQuipment’s optional VDAS®.

For water hammer investigations, students adjust valves to create a steady flow from the header tank through the pipe. To create the water hammer effect, students shut the quick-closing valve. VDAS® displays and records the passage of the acoustic wave as it passes back along the water hammer test pipe, past each of the pressure transducers.

Learning outcomes

Investigations into the transient effects of pipe surge and water hammer caused by changing flow rates in pipes including:

- Demonstration and analysis of pipe surge

- Demonstration and analysis of water hammer

- Determination of frictional head loss between reservoir and surge tower

- Determination of pressure profiles

- Determination of velocity of sound in the test pipe