The guest author for this blog post is Sean Hainsworth, Aeronautical Engineering Lecturer at Milton Keynes College.

Given the enthusiasm of the students and feedback from the last blog post, we embarked on stage two of the Christmas testing. Many people have been asking about the sleigh, which is a good point. Initially the students needed to work out if a clean unloaded deer was viable and as we found out - it was.

Sleigh Fabrication and Test

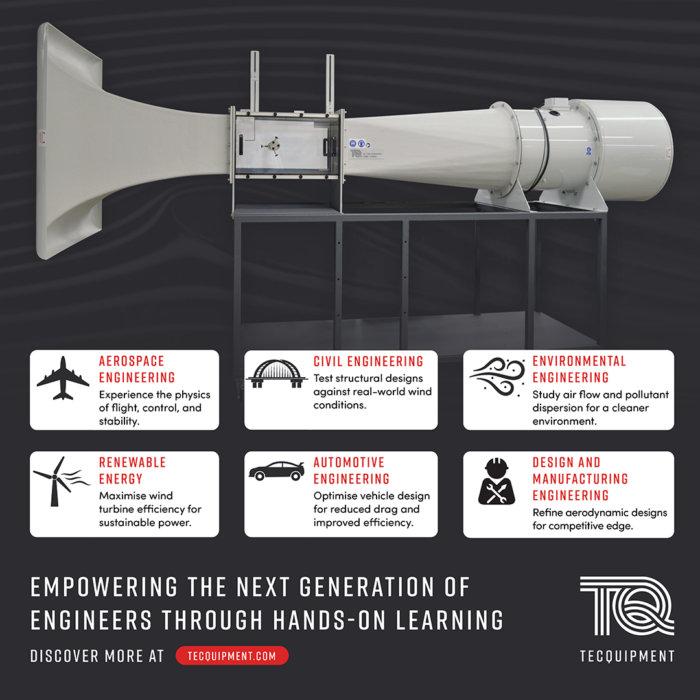

So to stage two. The elves (AKA students) were tasked with building a miniature to scale sleigh. Out of the welding bay, they had to perform quality testing that involved the piling up of mini parcels in the sleigh. Check, check, check and it was ready to enter the wind tunnel.

The students attached the sleigh to the lift and balance kit on the wind tunnel, turned it on and ramped up the power. The students made adjustments, took readings from the display panel and set-to with the maths. The upshot was, that it is possible for reindeer not only to fly, but also fly with a sleigh.

How Does it Work?

My students and I calculated that the best angle of attack for the sleigh is at ten degrees to relative wind, giving us an angle of incident between the sleigh and the reindeer of five degrees.

We also worked out that with the reindeer flying side-by-side in a row, this is how Santa controls his direction. Because the two rows of deer are independent they create wash in and wash out, thus giving Santa full authority control over his reindeer and sleigh. So boys and girls when you see Santa and his reindeer rushing and swooping through the sky you now know how it’s done – it’s all about creating the wash-in and wash-out.

Merry Christmas to one and all!

Sean Hainsworth of Milton Keynes College