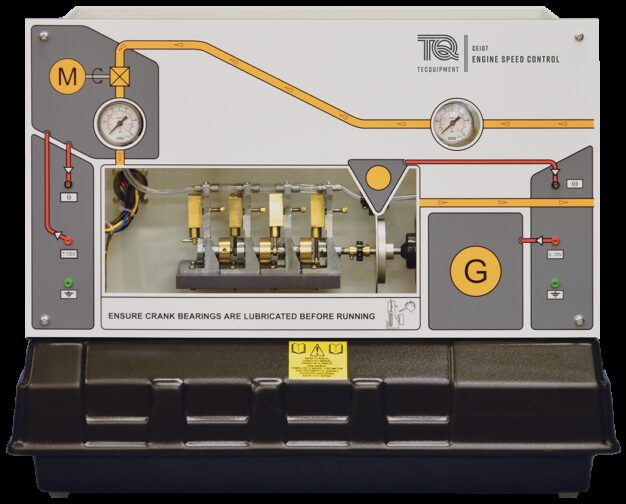

Experiment

CE107

ENGINE SPEED CONTROL APPARATUS

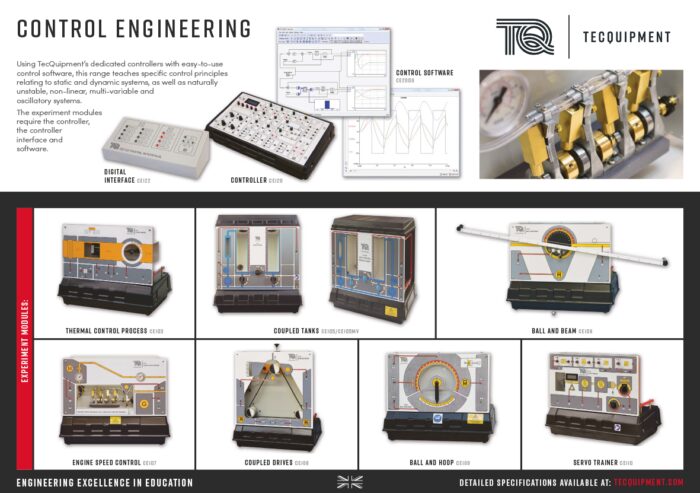

A compact self-contained bench mounting apparatus designed to allow students at all academic levels to investigate basic and advanced principles of control including control of non-linear systems and inner-loop feedback techniques.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611ENGINE SPEED CONTROL APPARATUS

The CE107 Engine Speed Control Apparatus shows the problems of regulating the speed of rotating machines, especially problems with non-linear control systems. It is a scale-model engine, driven by compressed air (not supplied) for safety. The basic purpose is to adjust a motorised valve to regulate the engine speed under load. A d.c. generator connects to the engine output and loads the engine.

More advanced experiments show:

- Non-linearity compensation using dither signals

- Multiple loop and minor loop feedback

- System modelling from step response information

- P+I control and root locus methods

The engine dynamics are similar to those of a typical ignition compression engine coupled to a dynamometer-controlled test bed. It is an ideal physical model to help engineering students at all academic levels to gain invaluable practical experience.

Learning outcomes

- The use of dither signals in the compensation of system non-linearities

- The measurement of system dynamics from step response information

- Inner loop feedback compensation

- P+I controller design