Experiment

TE96

AIR BEARING APPARATUS

A self-contained air bearing apparatus to demonstrate the performance of self-acting gas lubricated journal bearings including the phenomenon of half-speed whirl.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611AIR BEARING APPARATUS

A self-contained product that shows how a self-acting gas lubricated journal bearing works. It also shows the onset of ‘whirl’.

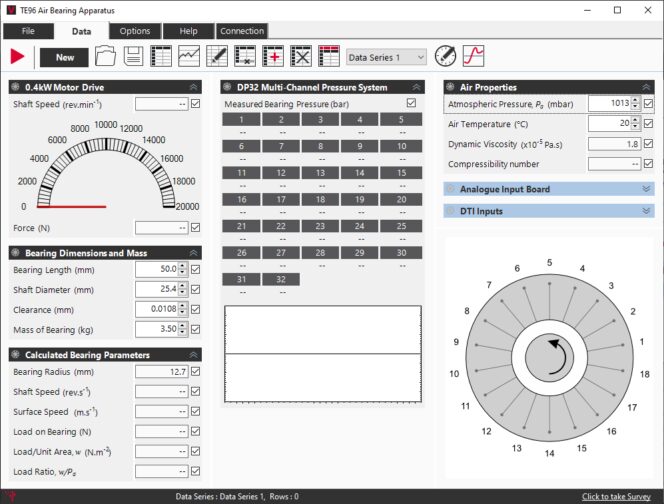

The main part has a variable speed motor that turns a belt drive. The belt drive turns a precision bearing shaft. The shaft has a high-quality surface finish and spins inside a vertically loaded bush. A hand-operated load control and load cell allow the user to apply and measure the load on the bearing bush. The bush has pressure tappings equally spaced around its circumference. The tappings connect to a multichannel digital pressure display unit.

A Motor Drive Module allows the user to vary the bearing speed. A speed sensor and the bearing bush load cell connect to the Motor Drive Module. This module displays the bearing speed and the load measured at the load cell. Both the Motor Drive Module and the Pressure Display Module fit into an Instrument Frame that has extra space for the optional frame-mounted VDAS-F.

Both modules include sockets to connect to the optional VDAS-F. For quick and reliable tests, TecQuipment can supply the optional VDAS® (Versatile Data Acquisition System). VDAS gives accurate real-time data capture, monitoring and display, calculation and charting of all important readings on a computer.

Learning outcomes

- Demonstrate how a vertical load affects the pressure distribution around an air-lubricated journal bearing.

- Demonstrate how bearing speed and therefore compressibility number affects the pressure distribution in the bearing, and how this compares with theory.

- Demonstrate the onset of ‘whirl’.