Installation, Commissioning and Training.

For this project, installation, commissioning, and training took place at the Universidad Ricardo Palma, Lima, Peru, by Ricardo over the course of a week. As the Subsonic Wind Tunnel package (AF1600S) is such a specialised product–even with the user manual provided, it was best for the equipment to be installed by someone with experience. The university decided to rely on TecQuipment’s expertise to ensure that the product would be fully functional and ready for the new semester. So, with Ricardo’s experience this meant that installation and training could be done effectively, allowing the students to start using a fully functional wind tunnel faster.

This project took 2 years to reach the finishing line. This was partly due to unforeseen events and the fact that upon purchasing it, and given its size, the university decided to construct a new building to accommodate it. Like most customers purchasing the AF1600S wind tunnel, space is an important factor. As this is the largest product produced by TecQuipment the recommended minimum room dimensions to accommodate a product of this size is 14 meters (length) by 6 meters (width) and, due to its weight, it could only be fitted on a ground floor. So, with the building completed we were able to ship the product and agree an installation and training date.

During product installation

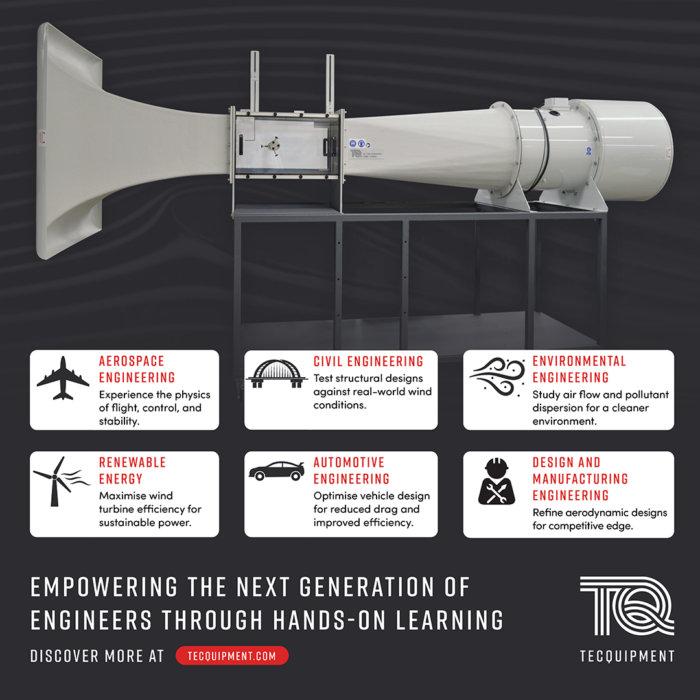

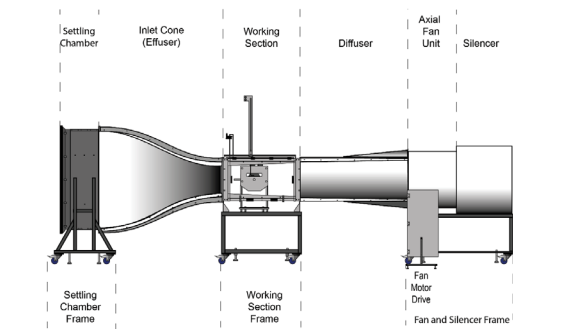

When the wind tunnel arrived in Peru, each part of the tunnel needed careful assembly. It was assembled in 5 different sections by connecting the Settling Chamber to the Inlet Cone to the Working Section then to the Diffuser, Axial Fan Unit and finally the Silencer.

Four technicians helped Ricardo by setting up and carefully moving the wind tunnel into position in the new outbuilding. The first two days focused on setting up the wind tunnel correctly whilst the remainder of the week focused on thoroughly training the technicians and professors who would be using the wind tunnel for their labs and architecture classes. The university displayed openness and keen engagement during the training sessions, recognising the potential of the wind tunnel to revolutionise their course and facilitate easier learning. This was key: fully understanding the product and its teaching potential will ensure that students and lecturers can safely operate it. This gives us peace of mind that the product is being used safe and effectively.

A new realm of teaching possibilities with the subsonic wind tunnel

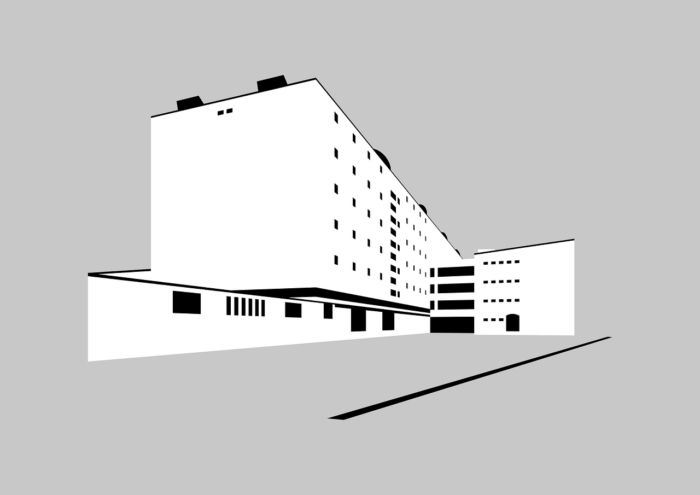

TecQuipment’s Subsonic Wind Tunnel Package (AF1600S) is normally purchased by mechanical, aerospace, or aerodynamic departments. But at the Universidad Ricardo Palma, architectural students will use this to test their scale models.

Why this will be important to their learning? With scale building replicas, students will be able to place these inside the wind tunnel and test either their designs or the materials used and then analyse data collected to improve their future designs. With the tunnel’s visible working section, where students can see the effect of different wind speeds on building models, together with data capturing features, the subsonic wind tunnel will help students easily analyse their models and simulate different wind environments which will help them understand how to design buildings for their intended environments. This will help students test their building designs for features and functionality, validate choice of materials, seeing results instead of just believing in theoretical methods, meaning they will construct better designs in the future.

The Subsonic Wind Tunnel will not only enhance architecture students’ learning of building design, but it will also offer them a greater appreciation of the effect of wind on building design (structure and form), the environment around the building and human response (vibration and perception of movement). This new product It is now a gateway for the university; they will be able to attract more prospective students which in turn will allow the university to expand its engineering program into key fields that are revolutionising Peru. There is also hope that the wind tunnel will be used by PhD students in their research and potentially attract increased funding for research.

A rewind as to why the subsonic wind tunnel was purchased.

The decision to invest in the Subsonic Wind Tunnel (AF1600S) from TecQuipment was influenced by several factors. Key professors at the university had prior experience using and studying with our wind tunnel in Europe. Our sales partners Powermatic played a crucial role in assisting the project and highlighting to the university that the wind tunnel's significance extends beyond functionality, contributing to the brand appeal of the university in attracting new students. So, the choice of such a flagship product like the Subsonic Wind Tunnel (AF1600S) plays a significant role; it is not solely about the functionality it offers but also about its visual appeal.

Equally, advanced research topics can be investigated with the wind tunnel, such as the possibility of improving the principles of natural ventilation in buildings. This will allow energy efficiency to be supported. If there is good ventilation, the use of ventilation equipment or artificial conditioning (cooling equipment) is reduced.

Lastly, the choice of the wind tunnel was driven by its build quality, being British-made, and the associated good reputation of TecQuipment. The decision was further influenced by the assurance of the 5-year product warranty, clear and easy-to-use manuals, and the availability of customer support when needed.

Conclusion to the Peruvian installation

The Subsonic Wind Tunnel (AF1600S) transcends from being a mere piece of equipment; it marks the beginning of a new era in engineering education with broad applicability to other disciplines. In a country where architectural innovation takes centre stage, the TecQuipment Subsonic Wind Tunnel becomes a catalyst for exploration, discovery, and a gateway to testing and perfecting innovative building designs. As our journey through the Peruvian installation concludes, we eagerly anticipate witnessing the impact of the Subsonic Wind Tunnel (AF1600) on the academic landscape of the Universidad Ricardo Palma in Lima, Peru.

We hope you found this article informative. If want to learn more about the Subsonic Wind Tunnel AF1600S click on the link here, or if you want to speak to a member of our friendly team about how a Wind Tunnel can be incorporated into your practical teaching then contact us here.