Understanding Digital Image Correlation (DIC)

Digital Image Correlation (DIC) is an innovative technique that utilises digital cameras to extract full-field data from images of a specimen's surface during testing. Unlike traditional methods, DIC provides comprehensive insight into material behaviour beyond stress-strain curves, generating full-field strain maps that visualise strain distribution and detect invisible cracks. DIC technology, available in 2D and 3D, offers engineers precise measurements and reliable data for material characterisation and structural validation.

Unlike traditional methods such as extensometers or strain gauges, DIC offers comprehensive insight into material behaviour beyond stress-strain curves. It generates full-field strain maps, allowing engineers to visualise strain distribution, detect invisible cracks, and analyse localised necking and yielding. Additionally, DIC facilitates the comparison of material behaviour between formulations and enables the analysis of strain in parts where traditional methods are impractical.

In educational contexts, DIC systems provide hands-on experience with advanced technology, empowering students to develop essential skills for the engineering field. With its ability to measure full-field strain and deformations, DIC plays a crucial role in driving innovation, enhancing education, and advancing research in engineering disciplines.

DefleX: Unleashing the Power of DIC in Education.

The development of DefleX®, TecQuipment's DIC product, is driven by several key market factors: the demand for practical educational tools, alignment with industry standards, advancements in DIC technology, the need for comprehensive teaching solutions, and the competitive landscape in the educational technology market.

1. Educational Needs: There's a growing demand for practical, hands-on learning experiences in engineering education. Institutions seek advanced tools and technologies to enhance students' understanding of complex engineering concepts, such as material behaviour and structural analysis.

2. Industry Relevance: As industries continue to evolve and embrace digital technologies, there's a need to prepare students with skills and knowledge aligned with industry demands. DIC technology is widely used in various industries for materials testing and structural analysis, making it essential for students to familiarise themselves with these techniques early on.

3. Advancements in DIC Technology: The continuous advancements in DIC technology have made it more accessible and user-friendly. DefleX® capitalises on these advancements, offering a student-friendly solution that simplifies the process of measuring and visualising surface deformations, strains, and displacements.

4. Market Demand for Comprehensive Solutions: Institutions seek comprehensive blended digital learning aids to complement hardware equipment that cater to diverse educational needs. DefleX’s versatility in application, covering uniaxial testing, biaxial testing, and shear testing, bending, and torsion testing, meets this demand by providing a single platform for various material and structural analysis tasks.

5. Competitive Landscape: With the increasing competition in the educational technology market, there's a need for innovative products that offer unique value propositions. For students at both undergraduate and postgraduate level DefleX’s integration of DIC technology into the educational environment sets it apart as a cutting-edge solution that addresses the evolving needs of engineering education.

Bridging Theory with Practice: DefleX

DefleX®, serves as an invaluable digital teaching and research aid for a wide range of engineering courses, offering a student-friendly solution to virtually see how materials behave in real time while being subjected to various loads.

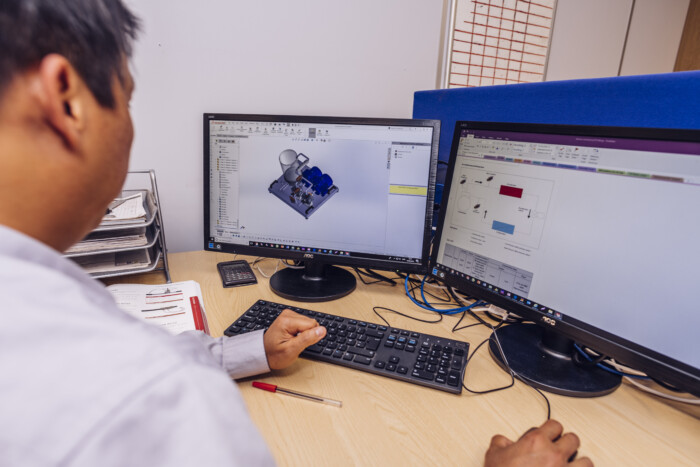

Equipped with camera measurement and image processing software, DefleX® enables the analysis of motions, displacements, and strains. By applying a speckled pattern to the target surface area and recording footage using a camera, the software tracks changes in the object's shape and size, allowing for the determination of deflection, displacement, and strains. This real-time visualisation of data through vectors and colour maps enhances students' understanding of material behaviour under different loading conditions, making DefleX® a versatile tool for various tests and an ideal introduction to optical extensometers and DIC technology.

Where DefleX brings real benefit to students in its measurement and analysis capabilities:

After an experiment has been performed, point probes, vectors, or bend lines can be used to track the displacement measured throughout the footage, providing further insight into the behaviour of the specimen under load.

DefleX® measures displacements in real-time, allowing for immediate analysis. Furthermore, it provides the capability to record live footage for later analysis in either playback or post-process mode.

Playback mode stores footage locally for immediate review, while post-process mode saves footage directly to the computer for further analysis.

The post-process mode, allows users to apply multiple probes to recordings, recalculate results, and export data to Excel for detailed analysis.

Key Benefits:

Incorporating DefleX® into engineering curricula isn't just about adopting a new technology; it's about empowering the engineers of tomorrow. By providing students with hands-on experience with DIC technology, educators can equip them with the skills and knowledge needed to thrive in the rapidly evolving fields of mechanical engineering and material science. From laboratory experiments to cutting-edge research (DefleX-PRO version required), DefleX® paves the way for a new era of innovation and discovery.

In educational settings, tools like the DefleX®-Edu provide access to DIC measurements, offering entry-level, low-cost solutions for academic training in solid mechanics and materials testing. These systems provide unrestricted measurement data acquisition with high accuracy and precision, empowering students with hands-on experience in DIC technology.

Additionally, DefleX® offers versatility in application, supporting various testing scenarios including uniaxial, biaxial, and shear testing, as well as bending and torsion testing. Its user-friendly design simplifies setup and operation, with calibration ensuring accurate measurements. The software enables live recording and post-processing analysis, with the flexibility to export data for further analysis in Excel. Moreover, DefleX® serves as an add-on to existing TecQuipment products or can be used as a standalone solution for strain analysis in various environments.

Learning Outcomes:

DefleX® enhances students' understanding of DIC technology and its applications in materials testing and structural analysis. By engaging in hands-on experiments, students gain practical experience in setting up experiments, calibrating equipment, and analysing data. The visual nature of the software makes it ideal for concept demonstration, catering to visual learners and facilitating interactive and engaging lessons. With sample data available for compatible products across various engineering disciplines, DefleX® empowers educators and lecturers to revolutionise teaching methods and create immersive learning experiences.

Investing in DefleX

With the purchase of DefleX®-2D, customers receive a comprehensive camera system, including a 12mm lens, black screen, light mounting arm, 2 LED lights, camera tripod, black and white marker pens, and two DefleX® Calibration Grids.

With DefleX®-3D customers receive the same equipment but with an enhanced camera system as this Digital Image Correlation (DIC) system is aimed at postgraduate students and researchers for (up to Technology Readiness Level 5).

A perpetual software license linked to a USB dongle key is also supplied, allowing installation on unlimited computers and use on the one where the key is plugged in.

Educators using the software can extend the perpetual licence by purchasing DefleX®-EduNet, that offers a batch of 20 annual licenses. Customers also have the option to purchase six additional lenses to optimise accuracy and tailor the system to their specific needs.

Conclusion

In summary, when engineering education is driven by innovation, embracing emerging technologies is key to unlocking new possibilities. With DefleX®, students are given the opportunity for a transformative journey into the realm of Digital Image Correlation. By bridging theory with practice and empowering students with hands-on experience, DefleX® heralds a new era of exploration and discovery in engineering education.

Are you ready to embark on this journey? The future awaits with TecQuipment's digital image correlation (DIC) system, DefleX®: DefleX | TecQuipment