This blog post has been written by TecQuipment’s Peter Mumford, who shares his knowledge and passion for sports science with an engineering perspective.

To enhance the performance levels of competitive running, carbon fibre plates are increasingly being put into the midsole of running shoes, with evidence correlating with claims to knock minutes off an average runner’s marathon time.

Carbon fibre (CF) can refer to the complex composite material of carbon atoms with a polymer base such as polyacrylonitrile (PAN) [1] to form a carbon fibre reinforced polymer (CFRP). Carbon must comprise of 92-99% of the total weight and typically measures between 5-10 micrometres in diameter. The material boasts relatively high tensile strength as well as a high Young’s Modulus, the stiffness that is determined by the ratio of tensile strength to tensile strain:

CF is commonly used in the civil engineering, aviation and automotive industries based on its specific strength, a strong material for a relatively light mass. Different composites and structures can yield differing qualities and therefore can be tailored to the exact purpose of its use.

Over the past 30 years CF has trickled down into sporting products implementation, with Nike recently refining and popularising it use through embedding a CF plate within the foam midsole of their running shoes. The sportswear manufacturer claimed that runners of all abilities could receive a 4% reduction in energetic cost for the same running speed [2], and therefore linearly correlating with performance improvements for the same energetic input. 3% of this derived from their revolutionary new light foam technology, reducing the inertia of leg swing, whilst the CF-plate was thought to contribute to a 1% reduction in energetic cost by increasing the longitudinal bending stiffness. Whilst a plate reducing energetic cost by 1% seems trivial, over the course of a marathon this could translate to shaving minutes off a preconceived time.

The plate spans the entire length of the shoe with curvature at the front to support the natural biomechanical principles of running at the forefoot. CF within running shoes consists of a high modulus as the plate aims to remain rigid, instead of flexing, when running. CF plates involve increasing energy return through the runner’s gait cycle based on the energy storage mechanism it creates. The plate and midsole foam aim to provide high compliance (compression under force), stabilising the joints and protecting the working muscles, whilst also possessing high resilience (greater stored mechanical energy). A reduction in energetic cost and increased protection would allow a runner to delay the onset of fatigue and therefore significantly improve performance towards the latter stages of a marathon.

Various peer-reviewed studies [3] [4] correlate with said percentile improvements in the laboratory. The release of CF-plated shoes heralded an increase in record-breaking runs, such as the historic breaking of the two-hour marathon barrier by Eliud Kipchoge in 2019, wearing a newer iteration believed to comprise of 3 carbon fibre plates and operating in excess of a 4% improvement. Since the technical advancements to running shoes and their widespread adoption by the masses as they became commercially available, average times recorded by elites and amateurs have dramatically shifted.

Poor fatigue limit is the primary physical issue however with CF plates; it can be difficult to predict the point of fatigue because of individual factors such as the runner’s physique and biomechanics. Due to the high impact nature of running, where approximately 2 - 2.9 times body weight ground reaction force is exerted every stride [5], it is projected CF–plated shoes can lose their spring effectiveness at approximately 100 miles of total usage, and so their use should be reserved purely for racing.

The concept of carbon fibre plates in shoes is not entirely novel, with podiatrists prescribing them within insoles as a means to maintain rigidity at the ankle joint for exercise and general lifestyle purposes. Yet for enhanced performance, this innovation polarises the running community [6], with claims the technology provides an unfair advantage through acting as a spring and returning an unfair excess of energy, akin to past debates surrounding amputee runners using carbon fibre prosthesis. Accessibility to CF-plated technology is also limited based on high consumer costs and Nike’s patents preventing other manufacturers (and their sponsored athletes) from utilising these innovations.

As a reflection of a surge in records broken and average times tumbling, recent regulations by World Athletics were applied to a trainer’s midsole (a 40 millimetre maximum foam height at the heel) as well as limiting one carbon fibre plate per shoe, with the aim to control the technological influence on performance. For as long as the technology continues to develop and redefine the limits of human endurance performance, the contentious issue of whether the sport is becoming a technical exercise rather than a test of pure human effort will continue to be debated.

Carbon Fibre Testing using TecQuipment’s Materials Testing and Properties Range

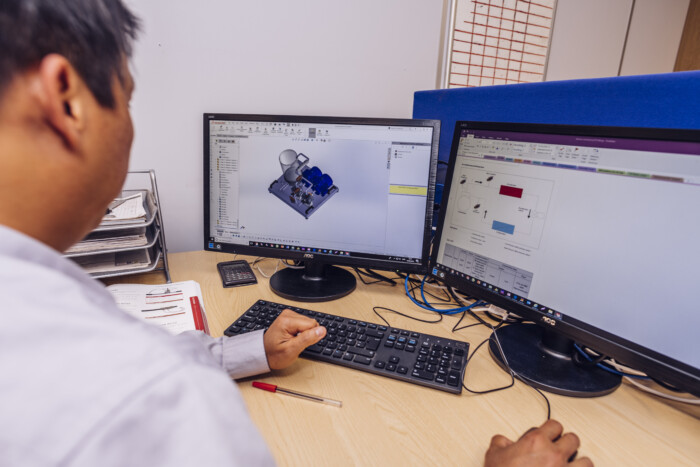

TecQuipment produce the Materials Testing and Properties range of teaching equipment which can be used to test the various properties of materials such as carbon fibre. This includes:

- Universal Testing Machine (SM1000) for carrying out destructive and non-destructive material tests.

- Stiffness – Bending and Torsion (TE16) for understanding the stiffness in bending of different CF composites with the same cross-section, enabling a variety of investigations into material stiffness including Young’s modulus.

Related to this, TecQuipment also provides the option to study composite materials in beams and struts, whether that is bending and flexing or elastic collapse or crippling with the Composite Beam Sets. Watch more in this video:

References

[1] Huang X. (2009). Fabrication and Properties of Carbon Fibers. Materials, 2(4), p.2369–2403. [Accessed 14th February 2019]

[2] Hoogkamer, W., Kipp, S., Frank, J.H. et al. (2017). A Comparison of the Energetic Cost of Running in Marathon Racing Shoes. Sports Med (48) p.1009-1019. [Accessed 14th February 2019]

[3] Hunter I, McLeod A, Low T, Valentine D, Ward J, Hager R. Running economy and marathon racing shoes. Rochester: American Society of Biomechanics; 2018. [Accessed 14th February 2019]

[4] Barnes KR, Kilding AE. (2018) A randomized crossover study investigating the running economy of highly-trained male and female distance runners in marathon racing shoes versus track spikes. Sports Med. 9-018-1012-3. [Accessed 14th February 2019]

[5] Nilsson J. and Thorstensson A. (1989) Ground reaction forces at different speeds of human walking and running. Acta Phsyiol Scand (136) p.217-227. [Accessed 14th February 2019]

[6] The Guardian (2018) Nike’s lightning shoes hint at power of technology to skew elite competition https://www.theguardian.com/sport/2018/jul/22/nike-shoes-vaporfly-sport [Accessed 14th February 2019]

Roy J.P., Stefanyshyn D.J. (2006). Shoe midsole longitudinal bending stiffness and running economy, joint energy, and EMG. Med Sci Sports Exerc. (38) p.562–569. [Accessed 14th February 2019]

Newcomb B. and Chae H., (2018). The Properties of Carbon Fibers Handbook of Properties of Textile and Technical Fibres (Second Edition) (2) p841-871. [Accessed 14th February 2019]

Wired [2019] The Science behind Nike’s new, even faster marathon shoe https://www.wired.com/story/the-science-behind-nikes-new-vaporfly-next-marathon-shoe/ [Accessed 14th February 2019]