Industry Open days - We’re pleased to welcome visitors to TecQuipment's factory and headquarters for our Monthly Open Days running on the second Wednesday and Thursday of every month throughout the year.

Experiment

DefleX-3D

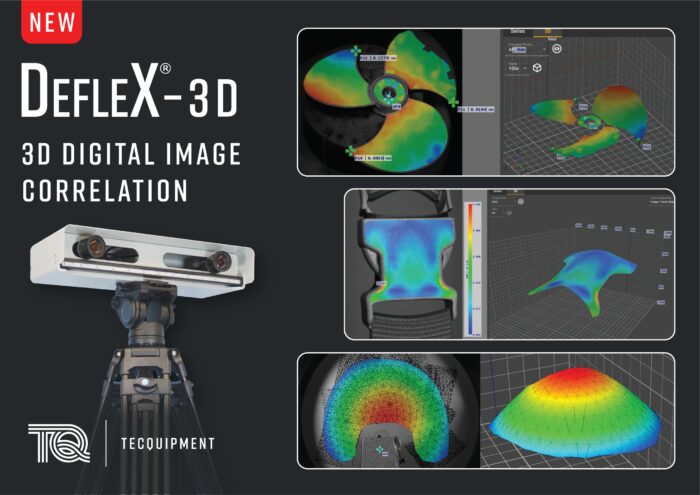

DefleX®-3D

From theory to reality - Seeing in microscopic detail

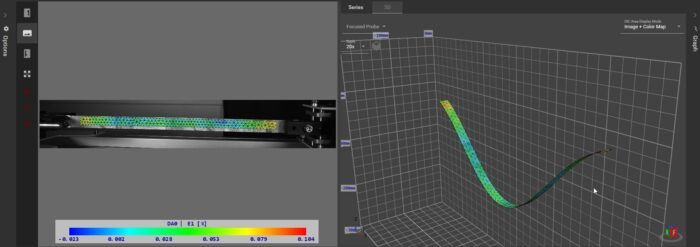

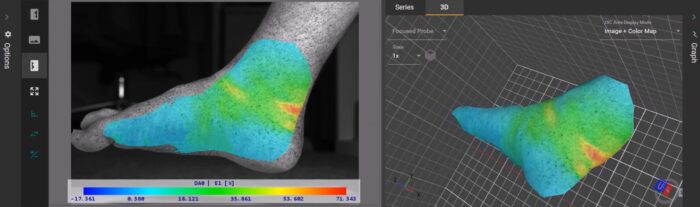

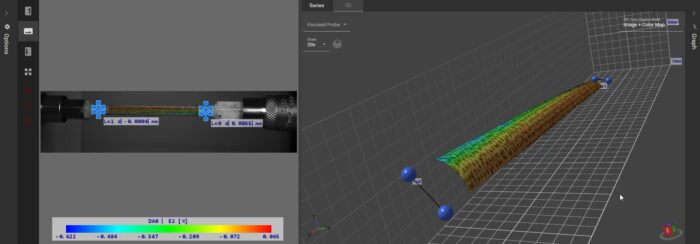

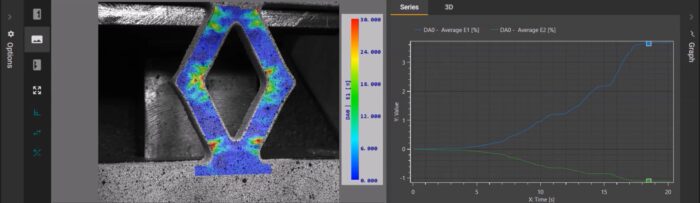

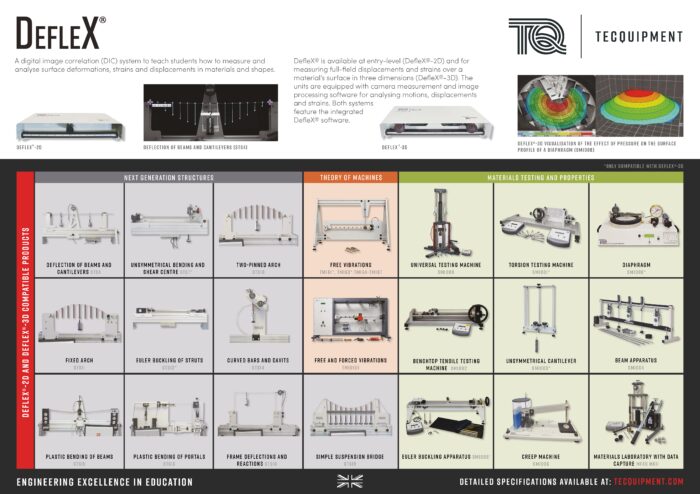

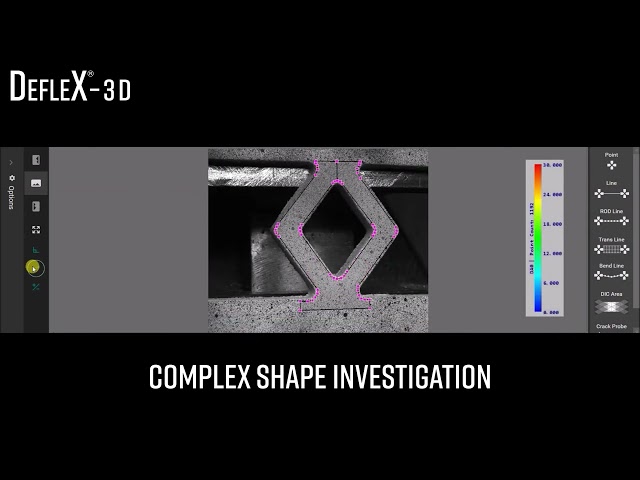

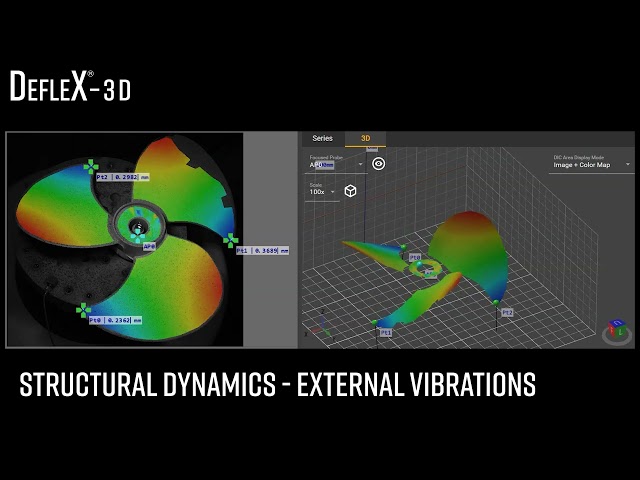

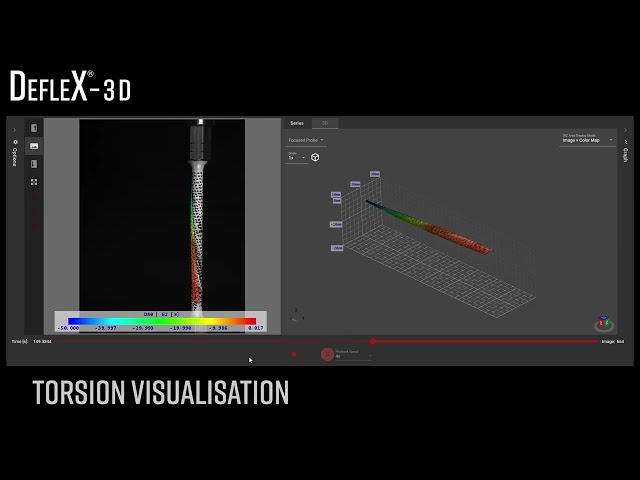

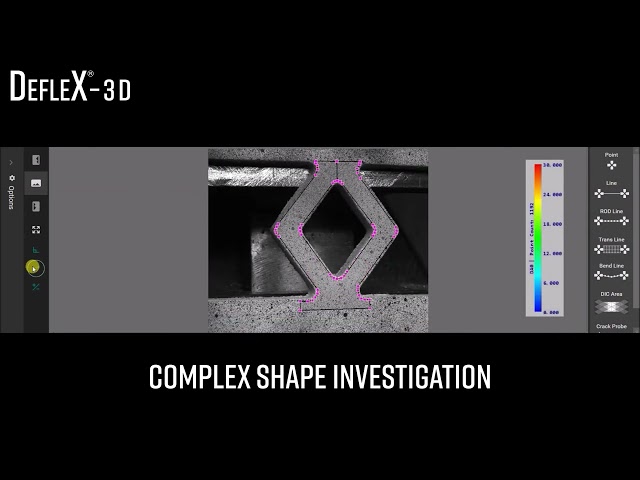

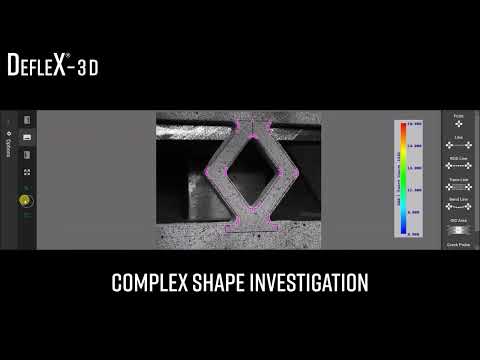

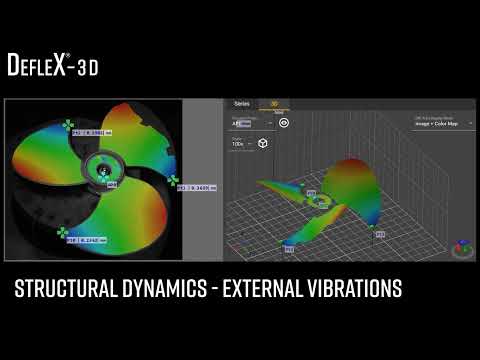

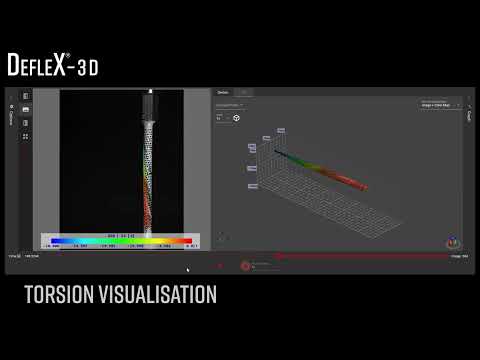

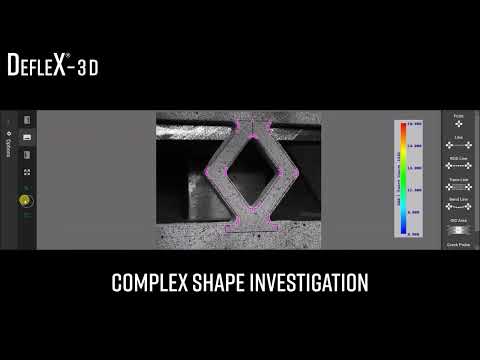

Combining theory, hands-on experimentation, visual learning, and technology evolution, DefleX®-3D is our teaching system helping students learn about 3D digital image correlation (DIC) that measures and visualises full-field surface deformations, strains and displacements.

Designed for teaching, it enables students to explore material behaviour, experimental mechanics, and design validation with real-world data. Simple to calibrate and quick to set up, using two digital cameras and image analysis software, DefleX®-3D captures surface changes in real-time or playback, enabling footage manipulation and data analysis whenever, wherever.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611DefleX®-3D

- Full-field 3D displacement and strain measurement

- Integrated dual 6 MPx CMOS cameras with LED lighting

- Data export to MATLAB, Python, ParaView, or spreadsheet programs

- All-in-one system with simple camera calibration

- Custom scripting and extended analysis in DefleX® software

Access the compatible product information poster here

Learning outcomes

- Gain high-precision strain/deformation data for analysis and demonstration

- Validate FEA models using real-world strain measurements

- Explore material behaviour, structural dynamics, and detect internal defects

- Develop skills in problem-solving, critical thinking, and data interpretation

- Understand limitations of traditional testing tools vs. non-contact methods

- Visualise complex systems like vibration, bending, buckling, and more

-

DefleX®-3D

DefleX®-3DDefleX-3D: an integrated DIC system, measuring material's surface full-field displacements & strains

-

DefleX®-3D

DefleX®-3DAn integrated DIC system for measuring full-field displacements and strains in 3D, DefleX-3D

-

DefleX®-3D

DefleX®-3DMeet DefleX®-3D!

-

DefleX®-3D

DefleX®-3DWhat can DefleX-3D do?

-

DefleX®-3D

DefleX®-3DApplication in Education for DefleX-3D

Available experiments

Recommended ancillaries

Ancillary

DefleX®-3D-TE1-TE5