Experiment

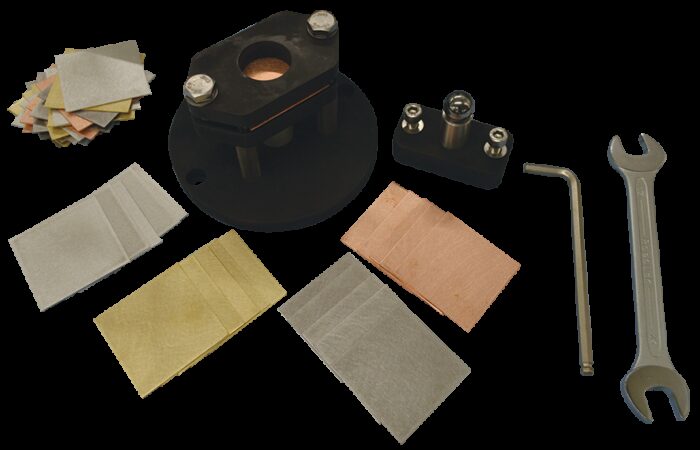

SM1000h

Cupping Experiment

Fits in the Universal Testing Machine (SM1000) for cupping tests.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611Cupping Experiment

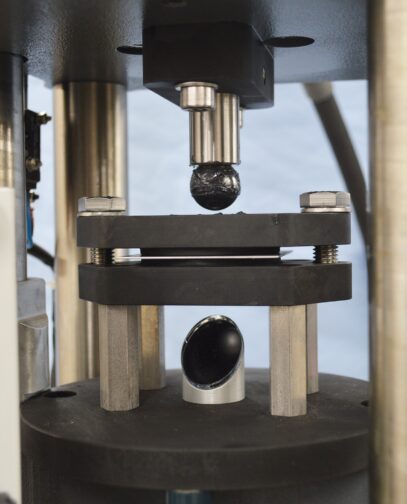

The Cupping Experiment (SM1000h) fits in the area above the loading platform of TecQuipment’s Universal Testing Machine (SM1000).

The penetrator is made of hardened steel, the cupping specimen is clamped between the clamping plate and the die plate. An angled mirror is placed below the die plate to enable easy viewing of the specimen rupturing.

The penetrator sphere is first lubricated then using the Universal Testing Machine it is pressed into the cupping specimen causing a cupped shape indentation to form. As more pressure is applied, the cup forms until it ruptures as seen in the angled mirror.

Hardness test specimens included (10 of each):

Learning outcomes

• An understanding of the limits of various sheet materials

• An understanding of the Erichsen Number, IE (the depth of penetration achieved when a specimen first ruptures

• An understanding of the difference between isotropic and anisotropic ruptures