Base Unit

MFP102

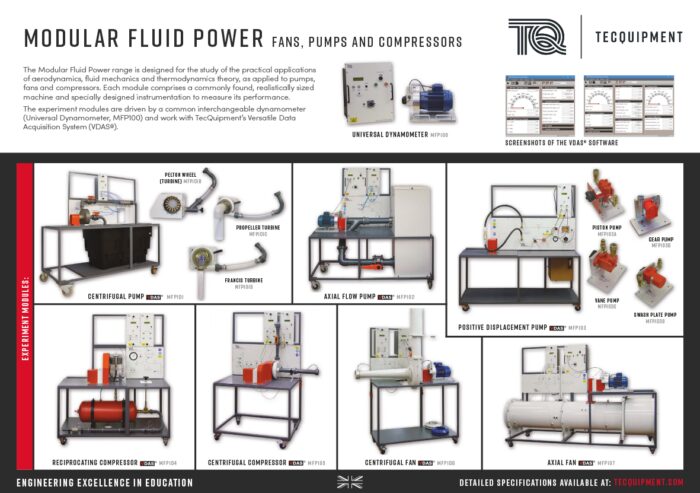

AXIAL FLOW PUMP MODULE

A self contained floor standing mobile unit consisting of a water reservoir, pump, calibrated nozzle and valves. It allows students to study and perform tests on an axial flow pump to understand how it works and calculate its performance.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611AXIAL FLOW PUMP MODULE

For use with the Universal Dynamometer (MFP100), the Axial Flow Pump Module is part of TecQuipment’s Modular Fluid Power range. The Axial Flow Pump Module is ideal for student experiments, demonstrations and projects. Axial flow pumps are common machines, used to pump water and other liquids. They can be as small as a few centimetres in domestic use, or up to a metre when used in large irrigation systems. They give high flow rates at a reasonable pressure. The pump fitted to this module has two sections - one fixed and one moving, each with a set of blades.

The module has an axial flow pump and instrumentation, all mounted on a robust, mobile trolley for ease of use. The module is for use with and driven by TecQuipment's Universal Dynamometer (refer to MFP100 datasheet). The Universal Dynamometer measures the speed, torque and power absorbed by the pump. Speed is fully variable up to the maximum allowable for the pump.

Water moves from a water tank through a calibrated nozzle. It then passes through the pump and down to a fully adjustable delivery valve. It then returns to the water tank. The delivery valve allows the user to gradually shut the downstream water flow for a range of pump performance tests.

Electronic transducers measure the pump inlet and outlet pressures, and the pressure difference across the nozzle. A digital display shows all the readings.

For quick and reliable tests, TecQuipment can supply the optional VDAS (Versatile Data Acquisition System). VDAS gives accurate real-time data capture, monitoring and display, calculation and charting of all the important readings on a computer.

Learning outcomes

- Variation of pump performance with speed

- Variation of pump performance with different outlet pressures and flow rate

- Non-dimensional performance curves

- Determination of the specific speed of the pump