Experiment

CE105MV

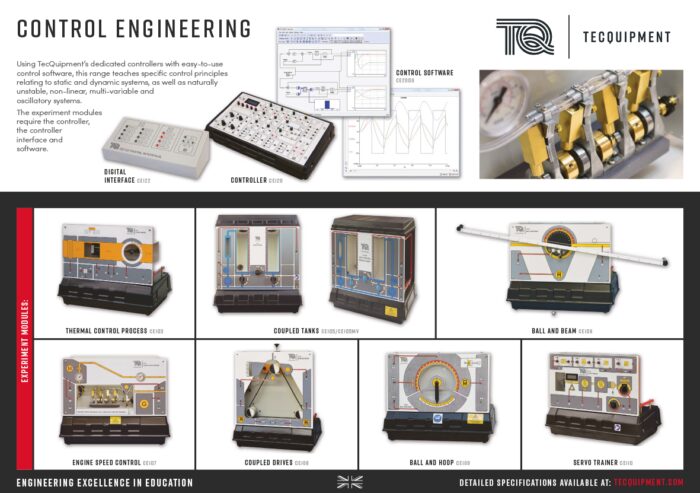

MULTIVARIABLE COUPLED TANKS

A compact self-contained bench mounting apparatus designed to allow students at all academic levels to investigate basic and advanced principles of open and closed-loop control of flowrate and liquid level in single and dual tank systems including multi-variable dynamics.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611MULTIVARIABLE COUPLED TANKS

The Coupled Tanks Apparatus investigates basic and advanced control engineering principles. This includes the study of static and dynamic systems. It is also an ideal system to use with other control strategies such as fuzzy logic.

The CE105 shows fluid transport and liquid level control problems in process control.

The basic control problem is to regulate the liquid level in one of the tanks by varying the speed of the circulating pump. The user guide includes experiments that cover system modelling using static and transient measurements, steady-state error analysis, transient response studies and Ziegler/Nichols tuning methods.

Each tank has a level sensor that gives output signals proportional to the water level in each tank. A scale on each tank allows students to check the level-sensor calibration.

A variable-speed pump forces water into the left-hand tank. A valve connects this tank to a second tank, if needed, for two-tank experiments. A rotameter-type flow meter shows the flow rate. An electronic flow meter measures the flow rate.

The CE105MV Multivariable Coupled Tanks Apparatus gives extra experiments. It is similar to the CE105 but with a second pump and flow meter. This pump forces water into the right-hand tank and works independently of the other pump. This gives more advanced experiments into the principles of multivariable control (both pumps work together to give the correct levels in the two tanks simultaneously).

Learning outcomes

- Calibration of transducer and actuator circuits

- System dynamics in process systems

- Design and operation of analogue proportional, proportional + integral, or proportional + integral + differential control controllers

- Steady-state errors and closed-loop transient responses

- Ziegler/Nichols controllers tuning rules

- Multivariable control

- Step-change tuning

- State feedback

- Flow control