What work are you undertaking as a Mechanical Engineer at TecQuipment?

I work as a mechanical design engineer and specialise in alternative energy, so currently I am focusing on three projects that will help expand this range of teaching equipment. The first project is a hydroelectric product, the second is a Heat Pump and the third is a Reversible Heat Pump. The goal is that by next summer at least two of these products will be available for our customers because we can see the increasing uptake of courses that are focusing on sustainable or alternative energy, and we want to evolve and provide products that our customers will value.

The Hydroelectric project

Onto the projects: we are focusing on hydro first because this area is experiencing strong demand from the market, and the product can be used with our existing flumes and hopefully if successful we’ll develop it to work on all our flumes.

The hydroelectric project focuses on generating power from the water stream across the flume. Currently this is in the prototyping stage of our product development cycle on a second version, and we are experimenting with a different set of results and testing outcomes. We might move to a third version as we are trying to devise the product, step by step, until we get a set of results that are good enough to be pushed to the market and will really benefit student learning. Student interaction is another reason why we are focusing on hydro first because you can look and interact with the product which makes it more interesting and stimulating for students.

With this project what is the important educational benefit?

For example, with the hydro project, a benefit for the students is being able to visualise the experiment and the product’s versatility. Undergraduates or postgraduates can use the product, as we offer a few open experiments; we can give the students a few specifications and they can 3D print their own blade and try their own experiments. So, we are not restricting the students to perform the set experiment, they can print their own blade and get different numbers and different results, so it’s an open experiment for the students. Again, the product is focused on improving student learning and interaction as the product will be touching the basic principles, but we are not trying to include lots of formulas into the experiments as we found that it makes the experiment difficult to interpret.

The Heat Pump project

What I find fascinating about this project is that it is the first product of TecQuipment that has been marketed as a heat pump and within the EC (environmental control) product range. Moreover, whatever we decide the learning outcomes are there will be a focus on power, and this will be different to other heat pumps that are in the market currently. With this project we are in the design and planning stage right now but soon this will be moving into the prototyping stage. We have a list of products, we already have a wind turbine dynamics and solar products, but we haven’t touched hydro and heat pumps, which is very crucial for TecQuipment and the alternative energy range I feel.

With this project what are the stages of the product development cycle?

With any project we have about seven stages ranging from concept design to producing the finished product and marketing it. But it’s not a straight-line process as we will often re-enter stages to ensure the finished product offered to our customers is the best it can possibly be. The stages are:

- Concept design - where you start broaching your ideas and pitching the concept to the engineering team for their opinions. Then you freeze/lock in the concept and start going ahead with this design.

- Detailed concept design - where you provide all the necessary details to make the product. What materials are needed, type of metal needed and so on, plus the costs of these and the overall cost to build the product. It also includes what components I want to buy or make internally in TecQuipment’s machine shop.

- Presentation to the board – here you create a detailed plan for the directors with design plans and learning outcomes and theories achieved with the product. (For this I must research and study theories behind it to brush up the content, as we don’t have the results or anything else available at this point. It is also where any improvement suggestions are made).

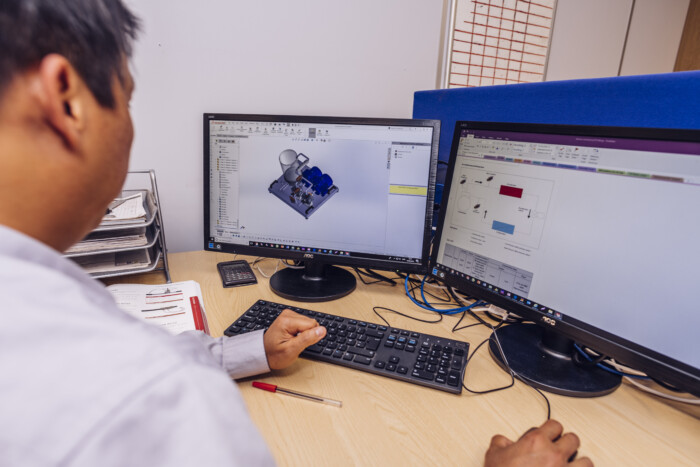

- Design – 3D build and run product simulations.

- Purchasing parts – where we put in the purchase orders, for all the parts needed to build the product, with input from the buying team.

- Production – product is assembled.

- Test – where we assemble the product and run experiments to get baseline results.

- Finished product - this is now a product that can be marketed and sold, so the last step is to get it painted and add the branding, then it’s the finished product ready for the customer.

What is it like working on projects at TecQuipment?

I have worked at TecQuipment for over a year now as the mechanical design engineer, specialising in alternative energy, working on three projects, starting off with a hydroelectric project. When I first joined, we were looking at which projects I should focus on first, the heat pump or hydro project and decided it was better for me to start with a smaller project - for a beginner and get to know the company and the industry first. By doing it this way I got to know the TQ culture and build strong team bonds.

What is the best aspect of the work you do?

What I like about the job is it suits my interests, and I can work on new product developments. What intrigues me is I can think and learn a lot here. The job constantly evolves and everyone who works here is supportive: if I don’t understand something, I can learn from the team explaining it. I have three years of experience in this field, but they are experts compared to me; they listen to your opinions but guide you and will give you space to experiment your thoughts.

When the job is interesting time flies by, and when the work is complex you can go through it in detail and really think about it and learn from it. The learning curve is huge, I’ve learnt a lot from the team and from the other products too. I am not restricted to just energy products, I can look at all products, if there is a problem when the product is being tested, I can see what the problem is even if I don’t know what the product is, but from that I get to know how it works.

Did studying your Sustainable Energy Engineering degree at university help you in this job?

I did a Masters in Sustainable energy engineering from the University of Nottingham. The course structure meant it touched all aspects of energy, considering the future, climate change, and emissions. This job is concerned with the mechanical design and producing new products in alternative energy. At university, my dissertation was on hydro so being able to undertake a real industry project on hydro helped a lot, however I struggled at university because much of it is solo working yet at TecQuipment you can bounce ideas off of the team and this really helps enhance the work and product capabilities. Every product I work on at TecQuipment is like a university presentation, with a seven-step process to a completed the project successfully. University also prepared me for project work and the challenges you might have to deal with.

Thank you for sharing a conversation with us, Sriram, on the project work you undertake as a Mechanical Engineer TecQuipment.

We hope you enjoyed finding out about what goes on inside TecQuipment and the people who make up TecQuipment!