Experiment

SM1003

UNSYMMETRICAL CANTILEVER

A bench mounting apparatus to allow students to investigate the deflections of unsymmetrical cantilevers.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611UNSYMMETRICAL CANTILEVER

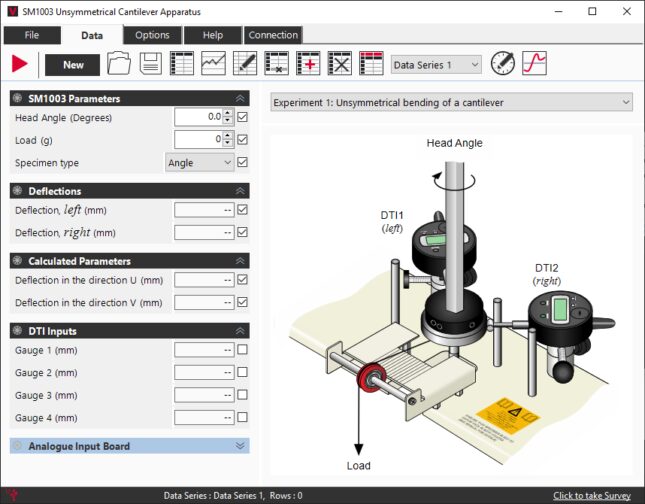

The Unsymmetrical Cantilever Apparatus allows students to load a cantilever and accurately measure its deflection in any coplanar direction.

Students mount a test beam vertically in a frame. The top of the test beam fixes to a holding ring that can rotate through 360 degrees.

Students apply a horizontal load in set increments (weights included) to the bottom (free end) of the test beam. Digital indicators measure the test beam deflections in two directions, at right-angles to each other. Each indicator has a socket and additional cable for connection to TecQuipment’s optional Versatile Data Acquisition System (VDAS®).

Students apply loads to the beam in set increments and record its displacement. Students can then rotate the beam to another position and repeat the experiment. This allows students to use the Mohr’s circle method to find the principal second moments of area of each section. To find the shear centre of a test beam, students attach a cross-piece to the free end. The cross-piece allows students to apply loads at different positions across and outside the section of the cantilever.

The equipment includes a user guide which describes how to assemble and use the equipment, with practical theory, experiment procedures and typical results. The textbook, ‘Structural and Stress Analysis’ by T H G Megson, is included with the equipment.

For quick and reliable tests, TecQuipment’s optional VDAS® gives accurate real-time data capture, monitoring and display, calculation and charting of all important readings on a computer.

Learning outcomes

Investigations into bending of unsymmetrical cantilevers, including:

- Vertical and horizontal displacement measurement for varying angles of applied load

- Demonstration that maximum and minimum vertical deflection occurs when horizontal deflection is zero

- Use of Mohr’s circle

- Experimental and theoretical determination of the principal moments of area of test sections

- Location of shear centre of each section