Experiment

H16

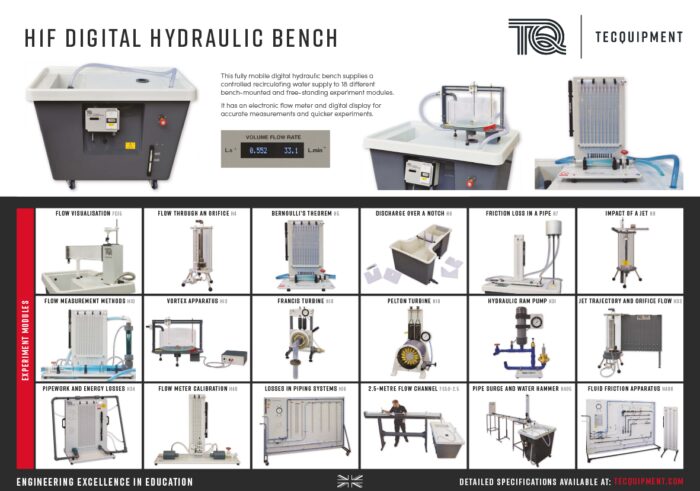

LOSSES IN PIPING SYSTEMS

An apparatus to allow students to investigate the friction losses in piping systems. The large open format of the apparatus makes it ideal for students working in small or large groups.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611LOSSES IN PIPING SYSTEMS

The Losses in Piping Systems apparatus comprises a vertical panel with two separate hydraulic circuits, colourcoded for clarity. Each circuit includes various pipe system components. The unit has wheels for mobility. They also help when storing the apparatus.

TecQuipment’s Digital Hydraulic Bench (H1F) supplies each circuit with a controlled flow of water. This allows students to study flow through the various pipe forms and components, and study and compare the pipe and component characteristics.

The circuits are made of small-bore copper pipe, commonly used in a wide variety of applications such as domestic central-heating systems. The small bore allows the circuits to include many pipe bends and components, while preserving effective upstream and downstream test lengths.

To measure pressure loss across components, the panel includes piezometer tubes and a pressure gauge. The pressure gauge measures pressure loss across valves; the piezometer tubes measure pressure loss across the other components. Included is a hand-pump to adjust the datum position of the piezometers.

Both circuits have common inlet and outlet pipes, controlled by valves. The valves are at the outlet to minimise flow disruption.

TecQuipment offers the optional ‘roughened pipe’. This can fit to the Losses in Piping Systems apparatus or be used by itself (fitted to a wall and connected to a hydraulic bench). It includes a pipe with a roughened internal bore, and pressure tapping points connected to a manometer. The manometer measures the pressure drop due to the pipe. Students compare their experimental results with Moody and Nickuradse charts.

Learning outcomes

A comprehensive range of investigations into losses in a variety of pipes and pipe system components, including:

- Straight pipe loss

- Sudden expansion

- Sudden contraction

- Bends with different radius

- Valves

- Elbows

- Flow in a roughened pipe: needs the optional Roughened Pipe (H16p)