Ancillary

TDX00A

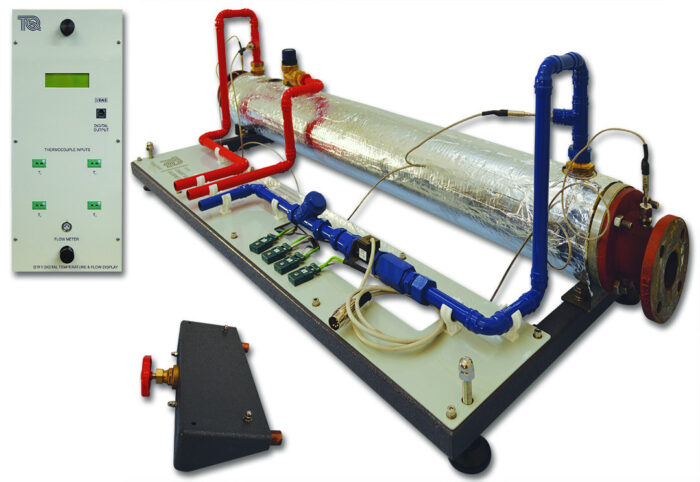

CALORIMETER FOR TD300

A fully instrumented exhaust gas calorimeter for use with the TD300 Regenerative Engine Test Bed to measure the heat content of engine exhaust gasses to determine the energy lost to exhaust in the energy balance for engines of various types operating at different loads and speeds.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611CALORIMETER FOR TD300

An exhaust gas calorimeter for use with TecQuipment’s Regenerative Engine Test Set (TD300). The equipment measures the heat content of exhaust gases and enables students to determine the energy lost to exhaust in the energy balance for single-cylinder, four-stroke petrol (TD301) and diesel (TD302) engines. The engines are separately available.

The main components of the Exhaust Gas Calorimeter are:

- Gas-to-water shell and multi-tube heat exchanger

- Control valve

- Instrumentation unit

The heat exchanger is mounted on a sturdy base plate. Exhaust gases from the test engine mounted on the test set flow through the tubes. A jacket of constantly flowing cooling water surrounds the tubes, and the heat content of the gases is assessed by measuring the cooling water flow rate and the inlet and outlet temperatures.

A hand-operated valve, which mounts on the control console of the test set, controls the flow of cooling water through the heat-exchanger jacket. Thermocouples measure the temperature of gas and water at the inlet and outlet. A turbine flow meter measures the flow rate. For safety, the heat exchanger also includes a pressure-relief valve in case insufficient cooling water is flowing. The instrumentation consists of a digital, four-channel temperature and flow display unit. This unit mounts on the instrumentation rail of the test set console frame and allows easy and accurate display and monitoring of data. In addition, the Exhaust Gas Calorimeter is fully compatible with TecQuipment’s Versatile Data Acquisition System (VDAS® available separately).

VDAS® enables accurate real-time data capture, monitoring and display, calculation and charting of all relevant parameters on a computer, making tests quick and reliable.

Learning outcomes

- When used with TecQuipment’s Regenerative Engine Test Set (TD300), the Exhaust Gas Calorimeter enables students to assess the heat lost to exhaust in the energy balance for single-cylinder four-stroke petrol (TD301) and diesel (TD302) engines.